Prefabrication

< Back to Approach

We are passionate about providing prefabricated and modular construction alternatives. By removing hours from the jobsite, eliminating multi-trade sequences and the dependence on good weather we can improve the overall schedule and provide increased certainty for our clients.

Leveraging our preconstruction capabilities, we look to push industrialized construction forward. To work with our clients, contractors and architects to design for prefabrication and continue to eliminate uncertainty throughout the project lifecycle.

Leveraging our preconstruction capabilities, we look to push industrialized construction forward. To work with our clients, contractors and architects to design for prefabrication and continue to eliminate uncertainty throughout the project lifecycle.

Benefits of Prefabrication

Speed

- Fast-track, systemized panel manufacturing and kitting

- Drastic reduction in construction schedule/sequencing

- Simultaneous site prep and prefabrication construction occurs

- Eliminate weather as a factor

- Reduced multi-trade subcontractor construction sequences

- Faster schedules/quicker execution

Value

- Multi-trade coordination completed and optimized prior to onsite construction

- Drastic reduction of onsite labor (6 men vs. 60)

- Reduced insurance and safety costs

- Reduced general conditions and supervision costs

- Owner realized returns from occupancy months ahead of time over traditional construction methods.

Providing kitting solutions, through strategic partnerships with our manufacturers, to provide the most efficient prefabricated and modular solutions.

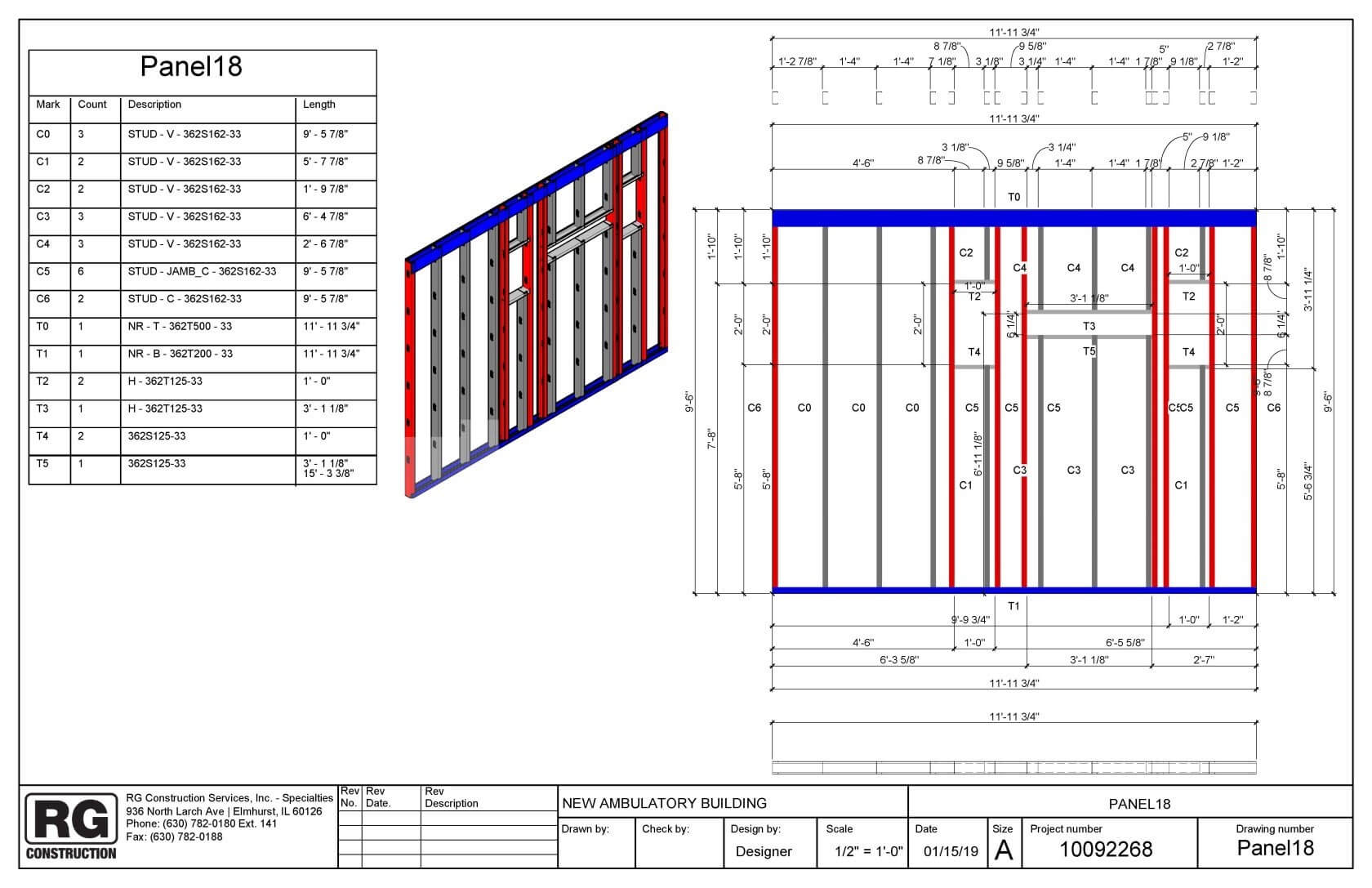

Cold-Formed Load Bearing Structures

Engage us on your next project and experience our collaborative design process to align your buildings design to an optimized structure with cost certainty.

Read more

StoPanel

As a leading StoPanel Affiliate in the Midwest, we are your trusted partner to provide a prefabricated envelope solution that meets your design and schedule requirements.

Read more

Featured Projects

Northwestern Medicine Old Irving Park Advanced Outpatient Care Center - Modular Exam Rooms

Working in conjunction with The Hill Group we modeled, coordinated and prefabricated 69 Modular Exam Rooms for Northwestern Medicine's Old Irving Park MOB. Through our VDC Services we leveraged our model coordination to LOD 400 to create complete material kits for each of the exam room pod types. Eliminating all onsite cutting and waste. Construction of the 69 modular exam rooms took 4 weeks.

“Innovation through Industrialized Construction. By pushing our clients, contractors and architects to innovate for DFMA (“Design for Manufacturing”) we can continue to improve how we deliver our projects by eliminating the constraints of labor and job conditions.”